Steam turbines work by converting the energy of high-pressure steam into mechanical energy to turn an electrical generator or other piece of equipment. The exhaust from the steam turbine being low pressure steam. There is however a type of technology which is worth considering instead of a steam turbine on certain applications. This being a steam screw expander.

The basis for this technology is a screw compressor in reverse. Many will be familiar with a screw compressor, two screws turn and effectively compress the medium between them. In principal the screw expander works in reverse, exhausting lower pressure steam out of it. Several companies offer this technology in the marketplace. Some use timing gears to ensure that the rotors work without damaging each other. These types of design can generally accept either saturated/wet steam or superheated steam. Other design types use a close to pure rolling contact between the moving rotors with the process fluid going through the machine effectively lubricating the moving parts. This limits these designs to saturated/wet steam applications.

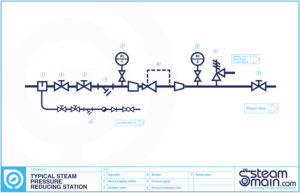

It is typical for steam to be generated at a higher pressure and for it to be used at a lower pressure. The pressure of the steam being reduced near the point of use by using a pressure reducing valve, or now potentially with a screw expander in parallel normally taking the steam load.

The reason for generating at high pressure and using at a lower pressure can be summarised below:

- Most steam boilers work better at higher pressures. This ensures that steam of the correct dryness is produced, and steam is generated in the most economical way. Reducing the pressure of a boiler can typically lead to a reduction of its output.

- The maximum allowable working pressure (MAWP) of the item of steam equipment, is lower than the pressure of the steam boiler.

- Distributing steam at higher pressure has the advantage of using smaller steam mains. This is due to the volume required being smaller the higher the pressure.

- By accurately reducing the pressure, steam can be used to provide tight temperature control for items of equipment. This is because the temperature of saturated steam is closely related to its pressure.

Potentially a screw expander can be installed in parallel with a pressure reducing valve station and used to generate electricity. Thought must be given to the use of the electricity, preferably locally on the same site as the steam system. Even if power is not going to be fed back into the national grid a G99 panel and consultation with the local power company is required (UK customers). This is similar to the steps required if power is generated through small solar or wind projects. By generating electricity in this way C02 and financial savings can result.

Other potential uses include waste heat applications where steam can be generated which can then be put through a screw expander.

Steam Main has a unique level of experience of integrating steam expanders to existing or new process steam systems to generate electricity. Steam Main can assist from up front feasibility work to check a potential project’s viability to the detailed design of the installation. Please contact us if you want to discuss further.