Why Steam

Steam is used in so many of the goods and services that we take for granted. In fact modern life would grind to a stop without the use of it! Which is why we believe that it has a very positive future.

Steam and modern everyday life

Food and drink

Beer, milk, bread, fries, jam; steam plays a vital part in their production and use.

- Ever wondered how the depressed cap on food jars are formed? This is done by using steam, thanks to its hygienic and condensing qualities.

- Did you know that steam is used extensively in commercial bakeries to produce bread? It is also critical to the proving stage of bread production, as well as ensuring that there is a nice glossy crusty crust on bread.

- In the production of potato chips (french fries), steam is used to peel the skins off. Its then typically used as the primary heat medium for heating the oil which the potato chips are cooked in.

- Many cereals use it in their production. For example Coco Pops, Puffed Wheat, and Puffed Rice. The whole grains are steam cooked in a pressure cooker. When the grains have been cooked, the pressure inside the pressure cooker is suddenly released. This sudden drop in pressure causes the moisture in the grains to flash into steam, puffing up the grains. The puffed grains can then be baked dry, and sweeteners added as required.

- Steam is used to ensure that chocolate can be pumped and be shaped.

- Steam is used in the preparation and cooking of food and beverage products. Either using steam injection or by using a jacketed pan type vessel.

- Shrink wrapping food. As its sterile so is ideal for this application.

- Canned food and pet food, its is used for cooking after the product has been put into the cans.

- Beer has been brewed for generations using steam. Whiskey too uses it throughout its distillation.

- Steam plays an important part of milk processing, typically being the primary heat medium for pasteurisation.

- Steam plays an important part of the sugar production and refining process.

Electricity and Steam

Without steam and the turbines, the lights would go out!

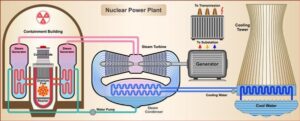

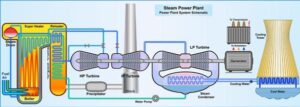

- A coal, oil or nuclear power plant would not function and generate electricity were it not for steam and the steam turbine. The lights would literately go out! It is estimated that approximately 80 percent of the world’s electricity is generated by steam turbines turning their attached generators. Coal, oil, and nuclear power plants simply generate lots of heat from their burning or fission process. This heat is used to turn water into high pressure steam. This is used to turn a steam turbine at thousands of revolutions per minute, which is connected to an electrical generator. This electrical generator then generates electricity which is fed into a national electrical grid.

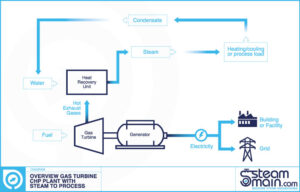

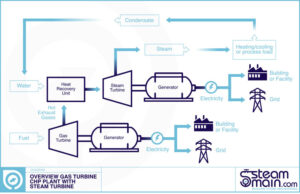

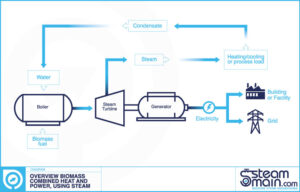

Combined heat and power

- Combined heat and power (CHP), is the generation of useful thermal and mechanical energy simultaneously. The benefit of CHP is the efficiency advantage when compared with conventional central station power generation. A CHP systems typically consist of; prime mover (heat engine), generator, heat recovery, and electrical interconnection. The types of equipment can vary depending on application and types of technology used. However steam is a vital part of a large number of CHP system designs to ensure that they can function.

Geothermal energy

- Geothermal power plants use steam generators and turbines to turn heat beneath the earth’s surface into electricity.

Solar energy

- The largest solar thermal power plant in the world, part owned by Google uses steam and steam turbines to convert the energy of the sun into usable electricity. The Ivanpah solar power plant in the USA generates electricity for about 140,000 homes. The plant generates electricity the same way that most of the world’s electricity is produced, namely by heating water to create steam, to turn a steam turbine. However, instead of burning fossil fuels to create the steam, by clever design the energy of the sun does it. Software controlled mirrors track the sun and reflect the sunlight to boilers that sit atop of three tall towers. When the concentrated sunlight strikes the boiler’s pipes, it heats the water to create superheated steam. The steam is then piped from the boiler to a steam turbine where electricity is generated. Solar thermal plants can easily incorporate heat storage during the day which converts the stored heat into electricity at night.

Any source of energy has an impact on the environment, however solar thermal power is as close to zero environmental impact as it gets for power generation, and steam plays a vital role in its generation.

Healthcare

- Sterilizing instruments and other medical equipment prior to operations in hospitals.

- Production of medicines and pharmaceutical products. Steam is used extensively both in the research and development of new drugs, and their subsequent production.

- Sterilizing contact lenses.

Homes and buildings

- Aerated building blocks (commonly called ‘breeze’ blocks) which are used for house and other building work thanks to their excellent thermal properties, are cooked and cured with steam in large steam autoclaves.

- Humidifying the air in museums so that paintings and works of art do not dry out and crack.

- Heating buildings from; hospitals, to hotels, to universities. Steam is also used as the primary heat source for heating hot water which is used in these same buildings.

Other uses, from semiconductors to tyres

- Electronic goods are a massive part of modern society. We are accustomed to having the latest TV, tablet, computer, phone etc. The semiconductor industry relies heavily on steam to ensure that the correct level of humidification is present in its manufacturing plants. This ensures a very high product quality.

- Production of corrugated cardboard, relies on steam to heat and moisten the paper and to cure the resultant cardboard after it has been glued together.

- Moulding tyres. There are millions and millions of cars on the road around the world. The most important part of a car are the tyres, and steam is used in their manufacture. A tyre is made by cooking it in a press with steam.

- Washing and ironing clothes. Commercial laundries use steam for tunnel washers and for the presses.

- Making of paper. Its used in the drying section of a paper making machine. This is done by using a series of steam heated rotated cylinders.

- Steam plays an important part in the production of condoms.

- Polystyrene foam is used in many different applications, from insulation in buildings, to packing of goods when they are transported. Steam is used in the production of polystyrene foam, for example in the shape moulders.

- Biofuels of all different types are increasingly being used around the globe. The use of steam is critical, as part of their production.

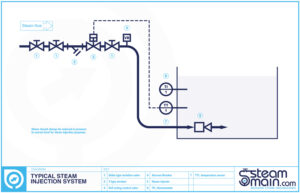

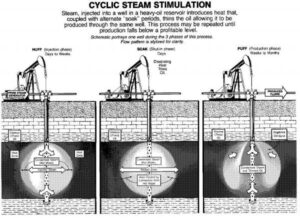

- Enhanced oil recovery. Steam injection is a method of enhanced oil recovery which is commonly used to extract heavy crude oil. It is used on oil reservoirs which are relatively shallow and which contain crude oils which are very viscous at the temperature where they are found. Steam injection is widely used in the San Joaquin Valley of California USA, the Lake Maracaibo area of Venezuela, and the oil sands of Alberta Canada.

The two main injection methods used are, Cyclic Steam Stimulation and Steam Flooding. A form of steam flooding that has become widely used is steam assisted gravity drainage (SAGD), in which two horizontal wells are drilled, one a few meters above the other, and steam is injected into the upper one. The heat of the steam reduces the viscosity of the oil to the point where it falls with gravity into the producing well.

Defence

- Steam is used on many modern and high tech naval vessels. The most visible of these being the massive nuclear powered aircraft carriers, as used by the United Sates and French Navies. The aircraft carriers have nuclear reactors which through their fission generate heat. This heat is used to turn water into steam. This is then used to turn the turbines, which turn the propellers, which enable the vast ships to travel at up to 31 knots.

Steam is also used on board to get the aeroplanes into the air when they need to be launched. Steam catapults are used to “shoot” the aircraft from standstill to their flying speed off the short carrier decks. Aside from making the ship ‘go’, and allowing the ships to launch their aircraft, steam is also used for heating, the production of hot water, and other tasks like heat for cooking.

- Nuclear powered submarines have the advantage of not needing air for the nuclear fission process, allowing the submarine to stay submerged for great periods of time. The heat from the reactors generate steam from water which turns the steam turbine to propel the craft.

Steam and the future

An area where the use of steam will change and develop is the manner of its generation. During the industrial revolution and much of the twentieth century the fuel used to generate steam was typically coal. While coal is still used in power stations the current fuel for general steam generation is typical gas, or oil.

In the future, the word ‘sustainability’ is going to crop up more and more. The great thing about steam is that it can be generated in new and different ways. This has been shown by the largest solar thermal power plant in the world, which uses steam and steam turbines to convert the energy of the sun into usable electricity. The Ivanpah solar power plant in the USA generates electricity for about 140,000 homes.

There are many research projects around the globe which are looking at new ways to harness the energy of the sun to generate steam.

A research team at Rice University in the United States, is currently working on converting solar energy directly into steam. They are claiming that nanoparticle technology will result in far better efficiency, coupled with a far smaller physical footprint, than existing photovoltaic solar panels. The system uses metal or carbon nanoparticles that absorb sunlight easily, converting the suns energy into heat. When these particles are submerged in water and exposed to sunlight, they heat up so quickly they vaporise the water around them which creates steam.

In Australia, a world first was achieved by the Commonwealth Scientific and Industrial Research Organisation (CSIRO), which has used solar energy to generate hot and pressurised ‘supercritical’ steam. The breakthrough that that CSIRO have achieved is the combination of pressure and temperature they have managed to achieve in the steam. This being 235 bara and 570 deg C. Existing solar thermal power plants around the world use subcritical steam, operating at similar temperatures but at lower pressure. If these plants were able to move to supercritical steam, it would increase the efficiency and help to lower the cost of solar electricity.

Supercritical steam is a breakthrough for solar energy and means that one day the sun could be used to drive the most advanced power stations in the world, currently only driven by coal or gas. CSIRO are also developing advanced solar storage to provide solar electricity at any time, day or night.

With sustainability in mind, it is highly likely that waste to energy type projects will vastly increase in number. This being due to new targets limiting the amount of landfill allowed, while at the same time their being new technologies for burning waste. New technologies for burning waste at very high temperatures, while at the same time carefully monitoring the exhaust gases, have largely overcome any objections from waste incineration. The power from these plants is used to generate steam and turn a steam turbine generating set. The power being fed into the national grid. Low grade heat from the plant can be used in a district heating circuit to heat local homes and factories.

The world record holding steam powered car, called the “British Steam Car”, was chosen by CNN and Time as one of the best innovations of 2009. Driven by Charles Burnett III and later by Don Wales, grandson of Sir Malcolm Campbell, both recorded new land speed records in 2009. The car is a great advert for modern steam engineering, as well as pioneering new technology which will feed into industry.

Another area where developments are being made is in the field of biomass. There are already biomass fired boilers that generate steam. Developments in biomass fuels can only increase their more universal usage.

We look forward to covering these exciting developments on steammain.com.

Advantages of steam

Steam can be easily, efficiently and economically generated by modern boilers from a variety of fuels and sources.

The heat produced by steam can easily distributed to the required point of use. Steam flows due to a pressure drop in the system, therefore costly pumps for circulation are not needed. The pumps needed for other mediums normally result in a considerable electrical load, and cost.

Steam has a high heat content meaning that in comparison to other systems relatively small diameter pipework is all that is required for distribution. Steam can be accurately controlled, only two port type valves are required reducing costs.

It is capable of transferring much energy with little effort. When steam condenses, this cycle efficiently transfers heat to the application being heated. The heat transfer properties of steam are high, so the required heat transfer area for the application is relatively small.

Steam is not flammable and contains no toxins. This makes it ideal for many industrial purposes.

Steam system basics

What is steam? When water is heated above a certain point it is converted into a vapour. This vapour is a white mist with minute droplets of water in the air. When water is boiling and continues to be heated in a boiler it will evaporate to form this vapour which is called steam. The amount of heat that is required to change water at its boiling point into steam is called the enthalpy of evaporation or latent heat. During the phase change time all the heat energy added is used to change the state of water to steam. Therefore there will be no increase in temperature of the steam/water mixture.

This phase is reversible. When a temperature gradient exists heat transfer will be the result. So when steam reverses this phase and condenses back into water it will give out exactly the same amount of heat that was added during its evaporation or latent heat stage.

Whilst no steam and condensate system is the same a typical saturated steam system can be looked upon as a loop or cycle. There are several stages and pieces of equipment that make up this loop. Below is a short summary of this loop or cycle.

Water supply and treatment; this is essential to allowing the steam to be produced for the steam and condensate cycle. Raw water is treated using a water treatment plant and program. This may range from a base exchange softener to a reverse osmosis plant. The treated water is then supplied to boiler hotwell feedtank (some systems may have a cold water make up storage tank too).

Boiler hotwell feedtank; is the place where the treated water is sent to. If condensate is returned from the process it is mixed with this treated cold make up water in a deaerator on the top of the tank. The boiler hotwell feedtank therefore acts as storage of hot water for the boilers. It is important that it is hot and therefore that it is properly lagged.

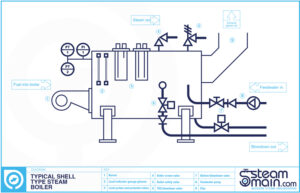

The Boiler; is the heart of a steam system. Without it steam could not be generated. The boiler is heated in many ways, such as burning fuels like gas, oil or coal, from burning waste, or from waste heat recovery from a variety of sources. The boiler turns water into steam. There are many different types and designs of boilers available. A typical boiler would have a blowdown system to remove impurities from the water in the boiler, a level control system to control the level of the water in it, and a burner or fire control device to modulate the amount of energy put into the boiler.

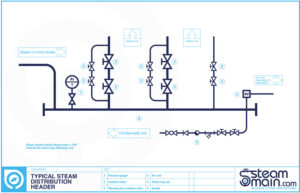

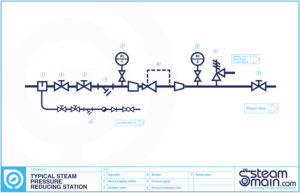

Steam distribution system; transports it to where it is required. It would typically consist of a pipework header, distribution main, and pipe off-takes from the main to the point of use. At places on these would typically be; steam trapping, metering, air venting, isolation valves, and pressure reducing stations.

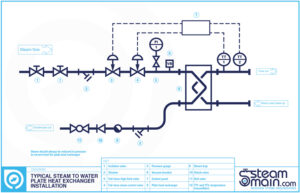

Steam consuming plant; uses steam as part of its process. This could be to heat a medium by exchanging the heat in the steam by the condensing of it against a heat transfer surface, or to heat a medium by injecting the steam directly into it. It could also be used to drive a mechanical piece of equipment like a turbine. The piece of steam consuming plant will typically have a control valve or similar to control the amount of steam used in it. It will probably have a steam trap or similar to remove condensate as it forms but close the trap when no condensate is present.

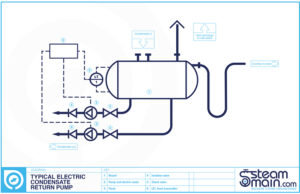

Condensate return system; collects the condensate formed from the steam consuming equipment (and from any distribution areas) and returns it back to the boiler hotwell feedtank. Condensate is a very valuable part of the whole cycle as condensate contains valuable heat, and treated water which can be re-used in the cycle again. Therefore it is very important to wherever possible return as much condensate as possible to the boiler hotwell feedtank. A typical condensate return system might consist of a condensate return header to collect the condensate back to a certain point, a condensate return pump (could be electric or steam powered), and a condensate return main to return back to the boiler hotwell feedtank.

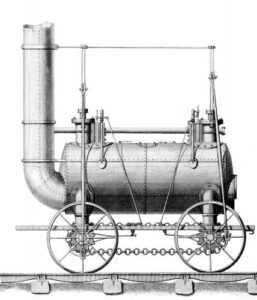

Steam, an illustrious past

Steam has a unique and illustrious history being a vital part of the first ever industrial revolution, as well as many others after. It was quite literally the driving force behind the first industrial revolution, which took place in Great Britain. Steam drove engines which powered mills and factories, pumps and other equipment for mines, trains to transport goods and labour across the country, at ports these goods could be loaded onto steam powered ships which transported these goods across the seas, and ships returned loaded with raw materials.

The industrial revolution marked a major change to human life. It can be argued that the history of humans can be divided into pre and post industrial revolution. Prior to the industrial revolution; GDP per capita head, life expectancy, income, diet, in fact every experience of humanity had been largely unchanged for a millennia, from the times when humans learnt they could cultivate their own food from the land. The industrial revolution changed everything, the living standards of the masses of ordinary people underwent sustained growth, the like of which had never been seen before. Today we are still reaping the rewards of the industrial revolution. A middle class family living in a developed twenty first century country enjoys a life which a king or queen could probably only just afford prior to the industrial revolution. The industrial revolution created not just innovation, this has happened before (the wheel for example), but sustained perpetual innovation that continued at a pace that had never happened previously.

At the heart of this sustained perpetual innovation was steam. It was first used to drain the tin and coal mines. The steam engines were used to pump water from the mines enabling deeper mines than before to be worked, as well as bringing the coal and tin to the surface. The steam boiler was fired from burning coal from the coal mine itself. Iron works were created to produce iron in large quantities for steam engines and boilers. To clothe the factory workers the textile industry grew rapidly, used steam engines to power their spinning and weaving machines. These machines massively increased cotton spinning output per worker. To transport good around the country railways were built and the trains that ran on the tracks were steam powered using coal as the fuel. To transport goods and raw materials around the oceans of the world, steam ships were constructed. Steam power was used to industrialise the process of printing, and the massive expansion of newspaper and book printing resulted. This led to rising literacy and political awareness.

The industrial revolution spread across the globe and led to the industrialised world that we now live in and which steam still pays an important part in.