Steam is the common source of heat in many process industries. There is a financial cost associated with the generation of this steam, so it is therefore imperative that its use is optimized as much as possible. One way on large industrial plants which often vent significant quantities of low pressure steam to atmosphere, wasting energy, water, and water treatment chemicals is the use of a steam thermocompressor.

What is a steam thermocompressor?

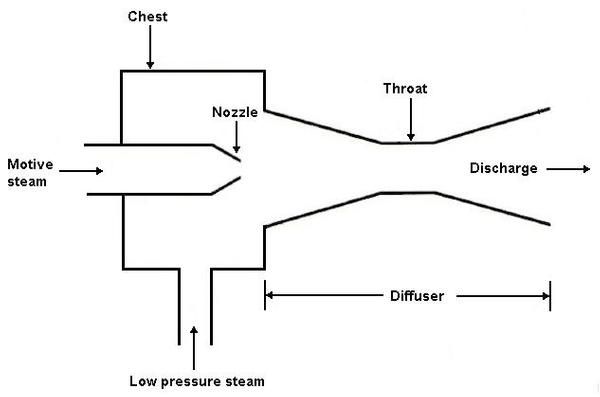

A jet compressor is a device that uses a fluid at high pressure to entrain a fluid at low pressure and discharge a mixture at some intermediate pressure. When both motive and suction mediums are steam the compressor is referred to as a “thermocompressor”.

Thermocompressor is derived from the process of using thermal energy or enthalpy of steam to achieve compression.

Higher pressure motive steam supplied to the thermocompressor expands in a converging diverging nozzle to convert pressure energy to kinetic energy. The low pressure steam supplied to the suction port is entrained into this low-pressure/high-velocity jet, where mixing occurs. The diffuser portion of the thermocompressor reconverts the kinetic energy of the mixture back into pressure. The intermediate discharge pressure is between the pressures of the motive and low pressure suction steam. The capacity of the device is dictated by the availability of higher pressure motive steam, motive and suction steam pressure, and discharge steam pressure requirements.

To recap, a thermocompressor essentially consists of three main parts:

- Nozzle

- Suction chamber

- Diffuser

Thermocompressor applications

Thermocompressors can be used in a large number of industries that use steam. Industries that successfully use thermocompressors to reduce their steam generation costs include; paper mills, sugar, textiles, food processing, petrochemical complexes, refineries, steel plants, tobacco, rubber and tyre industry, distilleries, dairies, and chemical plants. The most common application in each of the above industries is where significant venting of low pressure steam occurs, higher pressure motive steam is available, and a modest pressure boost could convert waste steam to useful steam for use onsite.

The low pressure, or flash steam recovered will depend on the condensate pressure, temperature and quantity as well as the pressure to which it will be flashed. The feasibility of such applications obviously depends on a number of factors which will be different from site to site and should be carefully investigated and calculated.

One of the largest users of thermcompressors is the paper industry. This has been largely due to the multiple benefits offered by thermocompressors when applied to paper machines.

Steam is used in the steam dryers of a paper making machine. To obtain the maximum heat from steam, ideally all the steam must be condensed. In practice, this never happens inside the dryer shell. Depending upon the dryer speed a percentage of the total steam entering the dryer shell is never condensed and leaves the dryer mixed with condensate as two-phase flow. The uncondensed steam in the condensate is called ‘blow-through steam’.

A thermocompressor system is used to inject intermediate pressure steam into the dryer by using high pressure motive steam mixed with the low pressure blow-through steam. The pressure control of a section of dryers can be achieved by a pressure control instrument throttling the thermocompressor and the makeup steam. Thermocompressors when used on paper machine dryer sections, offer the advantages of machine flexibility and high production capabilities. Each separately controlled dryer section can be looked upon as a single paper machine that will operate within the design limits of the thermocompressor. The result is not only improved energy economics but also improved paper machine productivity and quality.