The humble steam trap. A vital but often overlooked part of a steam system. It is easy for steam traps to be forgotten about when steam boilers, steam turbines, heat exchangers, and large impressive bits of plant take up the limelight. However steam traps and correct steam trapping is essential to a steam system.

There are a great many different types of steam traps designs and they function in different ways, but they have two main goals in common. This being to trap (stop steam escaping), but remove condensate when it is formed. If condensate is not removed dangerous water hammer can result. Escaping “live” steam can be expensive on fuel bills.

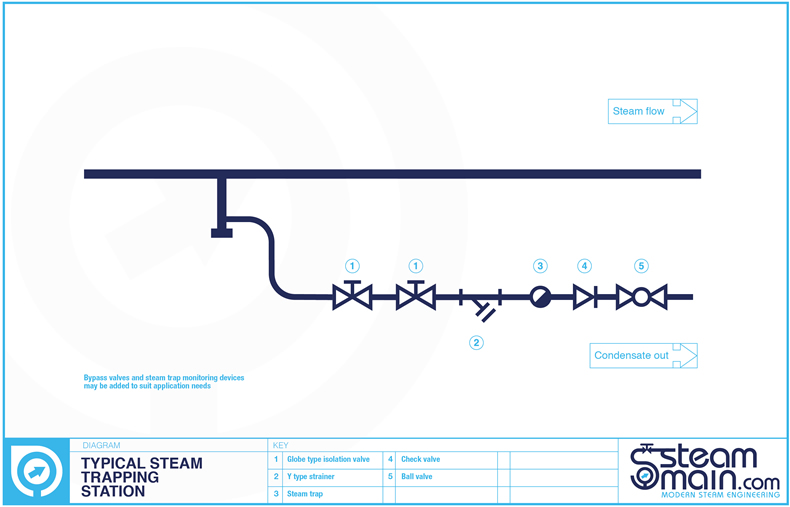

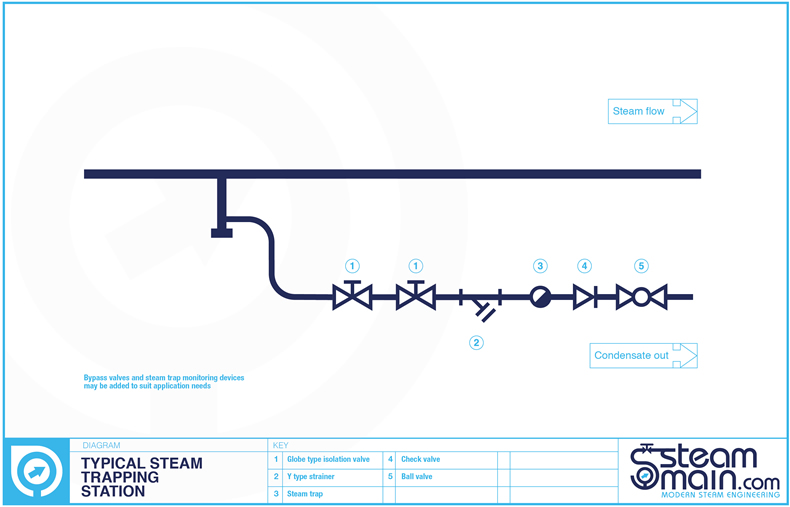

Steam traps are not normally installed just on their own. To aid maintenance and to protect the trap itself they are installed with other items. These will vary depending on the trap application (mains drainage) and location.

A standard steam trapping set that will cover most mains drainage and other similar applications can however be said to consist of, double isolation valves, strainer, steam trap, non-return valve, and a downstream isolation valve. A bypass may also be fitted to divert condensate during maintenance if appropriate. Thought can also being given to the fitment of a steam trap monitoring device or a sight glass.

An inventory of a sites steam trap population should always be kept, this to aid maintenance and inspection. To cross reference each steam trap set with the inventory record a tag round the pipework local to the steam trap is advisable.

So when thinking steam trap, think also of the trapping station as a whole.